| CONVERTING FACTORIES |

|

|

Hiscom Corporation has two desgnated coverting factories in Qingdao, China and Hanoi, Vietnam. There have been over 16years of strong cooperation in high Quality control for converting production.

Most of PE fabric has been made in Korea under Hiscom Corporation's quality control,shipped to the converting factory, and converted to covers as customers’ request in China factory and Vietnam factory.

|

China Qingdao converting factory details;

Sanguanmiao, Gongyeyuan-qu, Jiaodong-zhen, Jiaozhoi-shi Qingdao China

|

- Auto Heat-welder line (5 Heat welding heads equipped): 2 lines

- Manual Welder: 2 sets

- Two sides welder with rope hem: 2 sets

- Electronic Grommet(eyelet) Punching Machine: 19pcs

- Lock Stitching Sewing machine: 10pcs

- Chain Stitching Sewing machine : 2pcs

- Pressing Machine: 2sets

- Poly Vinyl Sealing Machine: 2sets

- Banding Machine: 2 sets

- High Frequency Welder :1set

- Ultrasonic Welder: 1set

|

Production Capacity :

|

- about 15 x 40ft containers for the general purpose Tarpaulin a month

- Specialized to Heavy duty General Tarpaulin and Special Covers with sewing

|

|

Vietnam Hanoi converting factory details;

No.4 South Thanh Ba Village Industrial Park, Thanh Ba District, Phu Tho Province, Vietnam

|

- Auto Heat- welder line (5welding heads equipped): 3 lines

- Manual Heat- Welder: 3 sets

- Two sides welder with rope in: 5 sets

- Electronic Grommet(eyelet) Punching Machine: 29pcs

- Lock Stitching Sewing machine: 30pcs

- Pressing Machine: 3sets

- Poly Vinyl Sealing Machine: 6sets

- Banding Machine: 6 sets

|

|

Production Capacity :

|

|

- about 45 x 40ft containers for the general purpose Tarpaulin a month

|

|

|

| CONVERTING DETAILS |

|

|

|

· HEAT WELDING

|

|

The Heat welding is the most important converting procedure. Therefore, we have been testing the Heat welding part's strength at every certain length to obtain over 80% of original PE fabric's properties in tensile strength, which is mostly over 90% (The tensile strength test machine has been set up on each factories for this test). We strongly focus on improving the heat welding and have romoved any faulty heat welding parts; over-heated parts, over-sliped parts, narrow welding parts, less than 80% heat welding adhesion parts, etc.

|

|

|

|

|

|

· SEWING

|

|

After Heat Welding and cutting procedure some of covers are required to be sewn according to the purpose of covers. To have relevant sewing strength we have been sewing 3 to 6 stitches per inch and the thread has been carefully designed and tested(inspected) for the high durability and the long term usage against UV together with PE fabric covers. Hiscom's special designed 204 and 206 polyester thread has been used for high UV exposed ourfield for long time and they are proven that they are prior to others in our field test and indoor UV test as well.

|

|

|

|

|

|

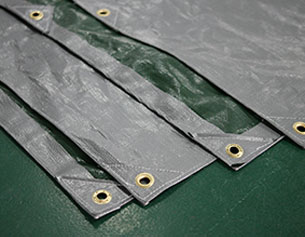

· EYELET(GROMMET)

|

|

The eyeles(grommets) are made of many different materials; Aluminum, Brass, Polycarbonate, Polyethylene in various sizes. We have been developing durable design for higher attachment of brass eyelet in efficient way and recently finish the Polyethylene(PE) Eyelet development as well as Polyethylene(PE) Eyelet punching machine; PE eyelet has several great features, 100% recycalble with PE cover together without detachement, Unbreakable when the cover is folded, Strong attachment to cover, No RUST.

|

|

|

|

|

| · 23mm Brass Eyelet |

|

|

|

| · Various 23mm Aluminum Eyelet |

|

|

|

|

|

|

· Hiscom's patent PE eyelet

|

|

|

|

· 23mm Brass Eyelet on reinforced triangles

|

|

|

|

· PACKING

|

|

The packing is also many ways. General tarps can put into a clear poly bag and bundled by strap and wrapped again with PE cover. Also, they can be into a general paper box or higher qualilty desplay box. The tarps(covers) will be folded in right size for box size, bundle size, or pallet size.

|

|

|

|

|

|

|

|

|

|

|

|

· LOADING

|

|

|

|

|

|

· FACILITIES

|

|

- Auto Heat Welder

|

|

|

|

- Two sides Heat Welder

|

|

|

|

- Sewing Machine

|

|

|

|

- Pressing Machine

|

|

|

|

|

- Stapping(Banding) Machine

|

|

|

|

|

- Eyelet(Grommet) Punching Machine

|

|

|

|

· ACCESSORIES

|

|

|

|